February 18, 2014

We had a request from NMUK to upgrade the existing light curtains on two Sinto Die Casting machines.

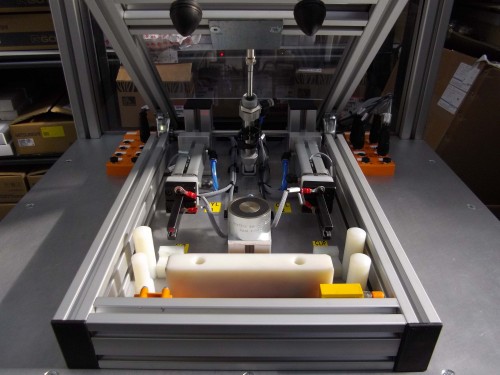

We replaced the existing rotary scanner with SICK mini-twin light curtains and upgraded the primary light beam unit from 110VAC obsolete units to new 24VDC units.

The existing electrical safety circuit was a hardwired system, we replaced this with a new SICK Flexisoft Safety PLC system, we connected a Proface HMI to the Safety PLC to provide diagnostics for Maintenace and Operators.

We stripped out the existing light curtains, electrical wiring and contactors.

We manufactured & installed new mechanical guards to mount the new SICK light curtains.

We installed the new wiring, Safety PLC & HMI for the new system.

We installed the Safety PLC Software and screen software for the HMI, we commissioned the system after developing a safety matrix to check all safety conditions possible with the new system. we worked very closely with the Facility Engineer to thoroughly check all scenarios.

We modified the machines PLC Software to provide interlocking with the new light curtains.

To ensure the machine started correctly we provided on-site support for production start-up.

We updated the electrical drawing package using AutoCAD for all changes made to the machines.

We also provided a document file incorporating all Safety Software, HMI Software, Electrical Drawings, Safety Matrix and Safety Software verification document.