October 7, 2013

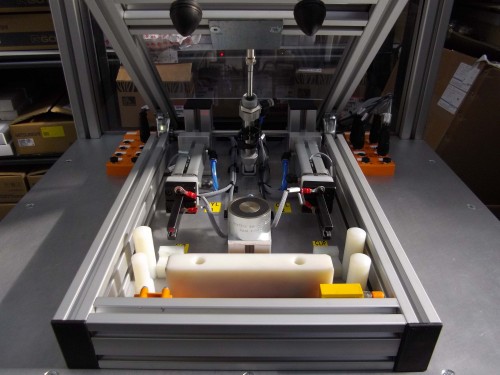

Calsonic Kansei required new PLC software and Robot programming for a jig and robot cell to supply Nissan with three variants of tail pipe for the Juke Nismo.

Our team of software engineers designed and developed new Omron PLC software to the requirements of the client. The engineer installed the software commands to allow the robot to perform its functions within a designated controlled area, the addition of a Proface HMI screen allows the operator to access functions of the Motoman robot.

The Motoman robot program was modified to suit the three variants, during commissioning sample parts were used to prove correct function of the program and to ensure all welds were correct.

We also provide ABB Robot programming on S4C & IRC5 Controllers to intergrate new jigs and fixtures, we develop the PLC Software for the new variants to poka yoke the sensors on the jigs, which can be Omron or Siemens, the HMI software which can be Proface, Siemens or Omron is modified to include the new operations and selections required for the new variants.

We install new routines into the Robot Programs and program the new routines to provide the required movements and welds for each variant.

We fully tested and commissioned all work carried out.